SLICE-QTC Four-channel Temperature Controller

SLICE-QTC four-channel temperature controller with sub-millikelvin temperature stability and set-point resolution.

Features:

- Four independent channels

- Configurable PID loop filters

- Sub-millikelvin stability

- Touch screen control

- Device-resident GUI & API

- 40 W of user-assignable control power

- 6 A/channel

- 18 V compliance

- TEC or resistive heaters

- External control of set point

- Interlock other devices based on temperature controller fidelity

Applications:

- Diode & quantum cascade laser

- Semiconductor amplifiers & tapered amplifiers

- Photonic integrated circuits (PICs)

- Nonlinear & photonic crystals

- Optical cavities, gas cells, and interferometers

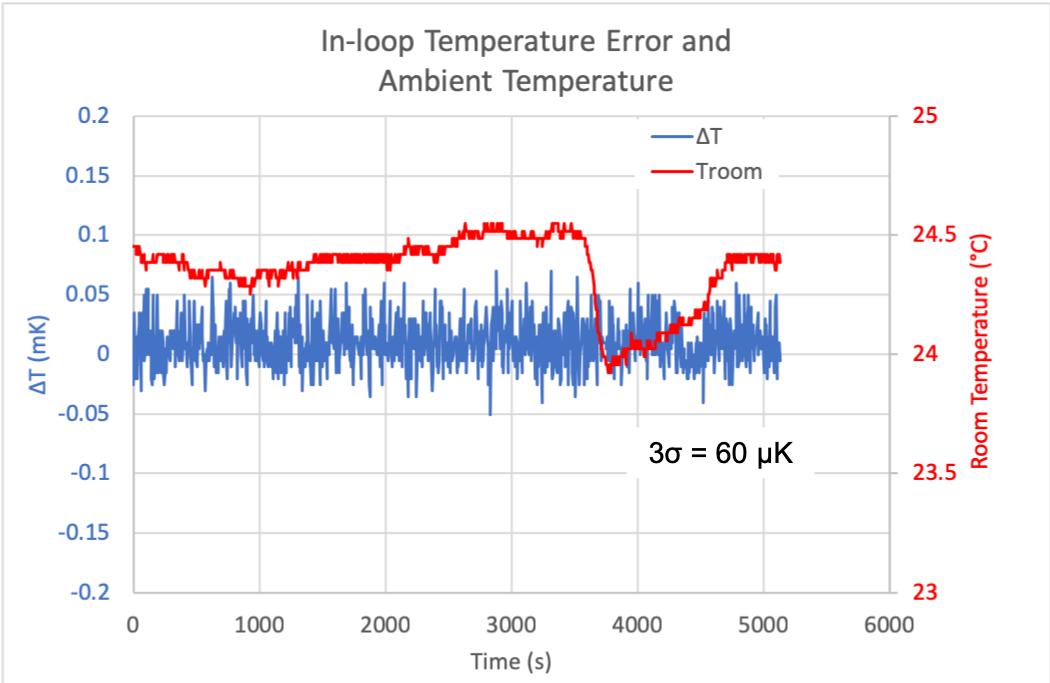

Stability of the temperature of an active D2-100 laser controlled by the SLICE-QTC

The SLICE-QTC PID Temperature Controller features four independent precision temperature controller channels for TECs or heaters for temperature stabilization and control of lasers, semiconductor optical amplifiers, tapered amplifiers, optical cavities, PICs, and non-linear & photonic crystals. The loops can be nested or control four separate systems. With widely adjustable PID corners and gain, it is possible to stabilize the temperature of your plant with sub-millikelvin temperature stability and set point resolution. Download our application note on stabilizing large thermal loads to sub-millikelving stability in the Attachments Tab.

Features like slew rate control and an output trigger allow you to trust your delicate photonic devices such as doubling crystals to the SLICE-QTC. You can set a maximum rate of temperature change and have confidence it won’t be exceeded. Safeguard your laser diodes by automatically shutting down the current if the the temperature goes out of range. Easily tune the PID temperature loop using the loop performance monitoring system.

The SLICE-QTC comes standard with four unterminated cables for connecting the SLICE-QTC to your thermal plant. You may also configure your order such that the cables are terminated with a DB9 connector. Use the drop-down list above to select your desired configuration. Order additional cables here.

The Vescent SLICE precision photonics control. Individually or working together, SLICE provides the performance you need on your benchtop, laser table, or in a rack.

| Feature | Specification1 |

|---|---|

| Channels | 4 |

| Looop filter Design | PID, adjustable time constants and gain |

| Control | Touch screen & rotary knobs API via USB 2.0 |

| Control Range1 | -20 to +120°C |

| Temperature Stability2 | <±0.2 mK |

| Set Point Resolution | ~0.2 mK |

| Capacity | 40 W total3 (20 W max per channel) 6 A/channel3 up to 18 V compliance4 |

| Sensor Type | NTC thermistor |

| Compatible Transducers | TEC or resistive heater |

| User-controlled Maximum Slew Rate | Yes |

| Power Input | 100 - 240 VAC; 50 - 60 Hz |

1Range can be extended by proper choice of thermistor

2 Over 1 hour

3User assignable over 4 channels, 20 W max per channel

4Device-controlled

Downloads:

- SLICE-QTC Four-channel Temperature Control Manual (wiki)

- SLICE-QTC Serial API Guide

- SLICE Firmware Update

- (System Controller 1.177 and QTC 1.52 available. Upgrade now for improved stability and an expanded feature set.)

Application Note: Temperature Stabilization of a Large Thermal Plant